Military aviation demands precision, durability, and adaptability. Aircraft engine stands, a critical component of maintenance operations, must meet the rigorous standards required to support military aircraft engines. These custom solutions ensure safe transportation, storage, and servicing of engines, enabling efficient maintenance workflows. This article explores the unique challenges of military aviation, the importance of certifications and partnerships, and strategies for future-proofing investments in engine stand solutions.

The Role of Engine Stands in Military Aviation

Military aircraft engines are highly specialized, designed to perform under extreme conditions. Maintenance operations for these engines require robust and adaptable tools. Custom engine stands play a pivotal role in ensuring:

- Safe handling during transportation and storage.

- Efficient maintenance by providing secure access to technicians.

- Protection against damage, which could compromise mission-critical equipment.

Engine stands must accommodate diverse engine types, such as the Pratt & Whitney F135 used in the F-35 Joint Strike Fighter or the EJ200 powering the Eurofighter Typhoon. These stands are engineered to meet specific military requirements, including extreme durability and compliance with stringent safety standards.

Military-Grade Durability: Meeting Extreme Demands

Military aviation operates in some of the most challenging environments, from desert heat to arctic cold. Engine stands must be built with materials and designs that withstand these extremes:

- High-strength materials: Structural steel compliant with ASTM A500 standards ensures durability under heavy loads.

- Corrosion resistance: Zinc-plated or stainless-steel components protect against rust in harsh climates.

- Shock absorption: Vibration isolators prevent damage during transport over rough terrain.

These features ensure that engine stands remain reliable even under the most demanding conditions.

Certifications: Ensuring Safety and Compliance

In military aviation, safety is paramount. Certified engine stands provide peace of mind by adhering to rigorous industry standards:

- OEM Certification: Original Equipment Manufacturer (OEM) approval guarantees compatibility with specific engine models and adherence to exacting design criteria.

- SAE Standards: Compliance with SAE Aerospace standards like ARP1840 ensures reliability and safety during operation.

- Annual Maintenance Plans: Certificates of Conformity (CoC) are renewed yearly to validate proper upkeep and functionality.

Using certified stands reduces risks such as engine damage or maintenance delays, which can prove costly in both monetary terms and operational readiness.

Strategic Partnerships: Leveraging Expertise

Collaboration with leading aerospace companies enhances the quality and innovation of custom engine stand solutions. For example:

- Lockheed Martin Partnership: As a key player in military aviation, Lockheed Martin’s involvement ensures that solutions like the F135 engine stand are tailored to specific operational needs.

- Global Networks: Companies like Aero Stands maintain extensive networks for rapid deployment of certified stands worldwide, minimizing downtime during Aircraft on Ground (AOG) situations.

Such partnerships foster innovation while ensuring that equipment meets the highest standards.

Future-Proofing Investments in Engine Stands

As military aviation evolves, so do its maintenance requirements. Future-proofing investments in engine stands involves anticipating changes in technology and operational needs:

1. Modular Designs

Engine stands with modular components can adapt to new engine models or maintenance procedures without requiring complete replacement.

2. Integration with Digital Technologies

Emerging technologies like IoT sensors enable real-time monitoring of stand conditions, enhancing predictive maintenance capabilities.

3. Sustainability

Eco-friendly materials and processes reduce environmental impact while aligning with global sustainability goals.

4. Long-Term Cost Efficiency

Investing in high-quality, durable stands reduces long-term costs associated with repairs or replacements. Certified products also minimize risks of operational disruptions due to equipment failure.

Why Choose Aero Stands?

Aero Stands specializes in delivering advanced solutions tailored to the unique demands of military aviation. With a focus on innovation and reliability, their offerings include:

- A comprehensive range of aircraft engine stands, designed for both commercial and military applications.

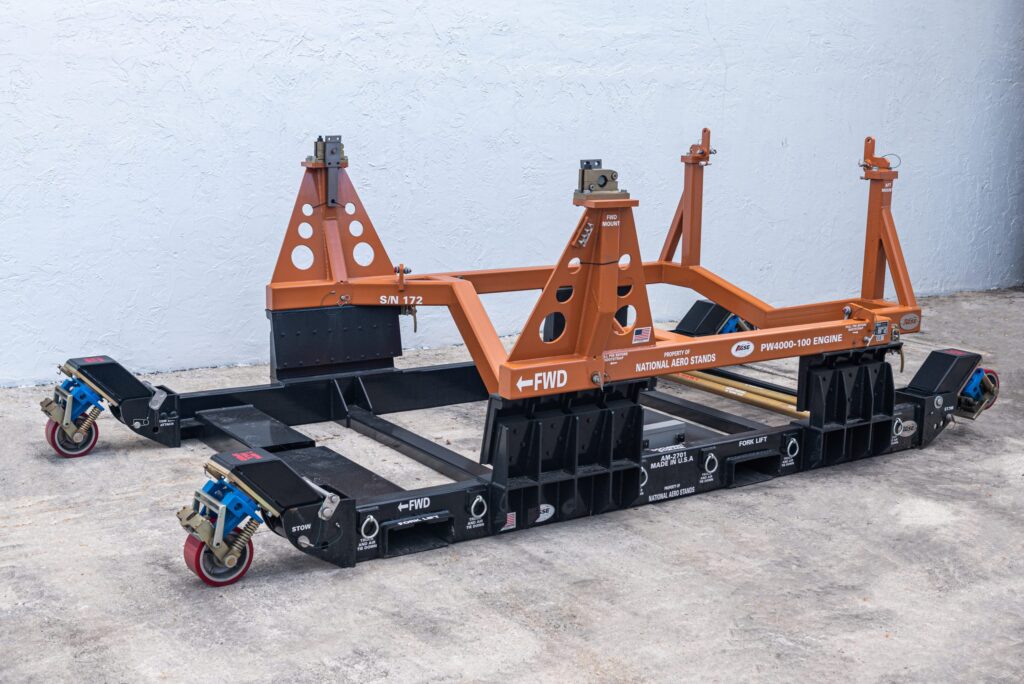

- Certified products like the PW4000-100 Stand, ensuring compatibility with major engine types.

- A global network enabling rapid deployment and support services.

By choosing Aero Stands, organizations gain access to cutting-edge technology backed by decades of expertise in aircraft maintenance solutions.

Conclusion

Custom engine stand solutions are indispensable for maintaining operational readiness in military aviation. Their durability, certifications, and adaptability ensure safe handling of valuable engines while supporting efficient maintenance workflows. By partnering with industry leaders like Lockheed Martin and investing in future-proof technologies, organizations can enhance both short-term performance and long-term sustainability.

To explore how National Aero Stands can support your operations with certified aircraft engine stands, visit their website today.